In the not-to-distant past, it was difficult to locate pollution prevention and sustainability information. Those days are gone. Now, we go to Google and we’re inundated. In this post, I’ll point you toward some resources that you may have forgotten about when you’re trying to locate information to solve a problem. Whether you’re an organization that wants to start a sustainability program or a seasoned pollution prevention technical assistance provider, there’s something on this list that will help you do your job better.

In the not-to-distant past, it was difficult to locate pollution prevention and sustainability information. Those days are gone. Now, we go to Google and we’re inundated. In this post, I’ll point you toward some resources that you may have forgotten about when you’re trying to locate information to solve a problem. Whether you’re an organization that wants to start a sustainability program or a seasoned pollution prevention technical assistance provider, there’s something on this list that will help you do your job better.

Topic Hubs and LibGuides

Topic hubs and LibGuides are similar. Both are curated collections of resources on specific topics that also include explanatory information. The only difference is the delivery platform. GLRPPR converted its Topic Hubs to LibGuides several years ago. Guides of particular interest to the P2 community include:

- Auto Salvage-Great Lakes Region Topic Hub

- Energy Efficient Schools and Students Topic Hub

- Integrated Pest Management (IPM) in Schools Topic Hub

- Mercury — Schools Topic Hub

- Technology Diffusion Topic Hub

- Green Business

- Green Libraries

- Mercury-Health Care Topic Hub

- Pollution Prevention 101

- Printing — Flexography Topic Hub

- Printing — Lithography Topic Hub

- Sustainable Product Design

- Sustainable School Design Topic Hub

The Pollution Prevention 101 LibGuide will be particularly useful to those new to the P2 field. It includes links to essential resources and training that will help get you up to speed quickly.

GLRPPR Sector Resources

GLRPPR’s sector resources are curated collections of documents organized by sector or topic. Each resource includes a link and a brief description. Sector resources includes links to fact sheets, manuals, videos, journal articles, case studies, and software tools. Browse by sector/topic or search by keyword using Google site search.

GLRPPR Webinar Archive

GLRPPR hosts two to three webinars per year. Recordings of these webinars are archived on our web site. The recording of our most recent webinar is embedded below.

GLRPPR Help Desk

If you have a sustainability question or problem you’re trying to solve, the GLRPPR Help Desk is the place to visit. You get one free hour of literature/web searching and will receive a response within a week. Note that we won’t often give absolute answers. Instead, we’ll give you references and let your draw your own conclusions based on the available information. We also won’t answer homework questions.

E-Mail Discussion Lists and GLRPPR E-mail Newsletter

E-mail discussion lists are a great way to tap the hive mind of your pollution prevention colleagues. GLRPPR members are automatically subscribed to the Roundtable regional e-mail discussion list. P2Tech is an international discussion list for pollution prevention and sustainability professionals. To subscribe to either list, contact Laura Barnes.

GLRPPR’s e-mail newsletter keeps you up-to-date on sustainability news, resources, events, and funding opportunities. Subscribe here.

P2 Impact

P2 Impact is a collaboration between GreenBiz and the Pollution Prevention Resource Exchange. Each month, P2 practitioners write about topics related to pollution prevention and sustainability. The goal of the column is to tell the P2 story to GreenBiz’s business audience. The archives of the column are available here. If you would like to write a column, contact Laura Barnes.

P2 InfoHouse

P2 InfoHouse, maintained by the Pollution Prevention Information Center (P2RIC), is a searchable online collection of more than 50,000 pollution prevention (P2) related publications, fact sheets, case studies and technical reports. It includes a vast number of legacy pollution prevention documents that were originally released in hard copy. The collection is searchable by keyword.

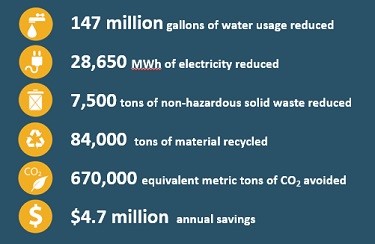

Zero Waste Network Success Story Database

The Zero Waste Network’s Success Story Database contains case studies that are examples of how real facilities saved money, reduced waste, and/or lowered their regulatory burden through innovative P2 practices. The studies are often written in a companies own words, with minimal editing.